Q345 steel property and specification

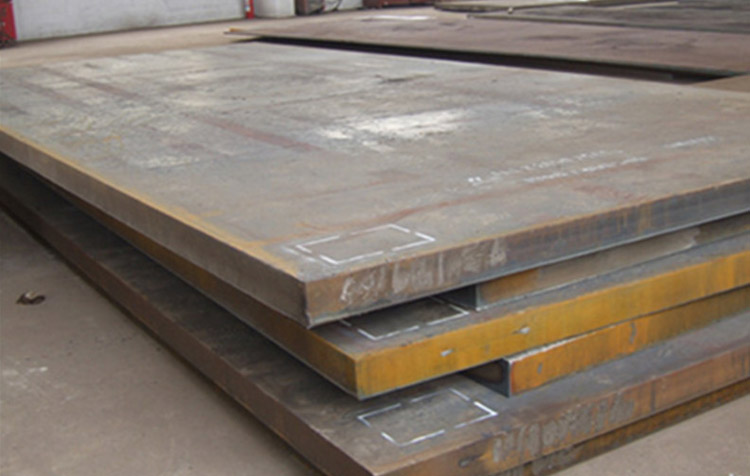

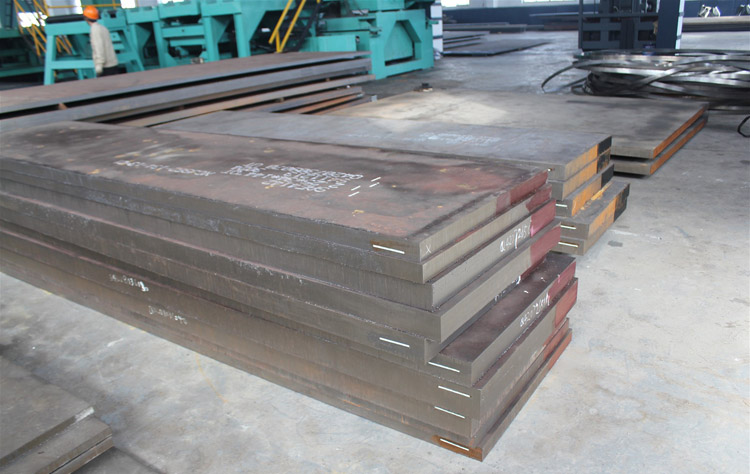

The major benefit of Q345 steel is its mild temper, easy to form and weld. Q345 steel is one kind of Chinese standardized low alloy, medium tensile strength steel made with a hot-rolling process, used for a number of manufacturing purposes. To some extent, the Q345 possesses the same property and composition of ASME A572, namely the Q345 is equivalent to A572.

This specification covers the standard requirements for Grades 42, 50, 55, 60, and 65 of high-strength low-alloy structural steel shapes, plates and sheet for applications in bolted, welded, and riveted structures in bridges and buildings.

The Q345 is a steel with less than 0.2 percent of its composition made up of carbon, less than 0.55 percent of its composition made of silicon and several impurities. This particular grade of steel is a general purpose manufacturing steel in construction equipment field.

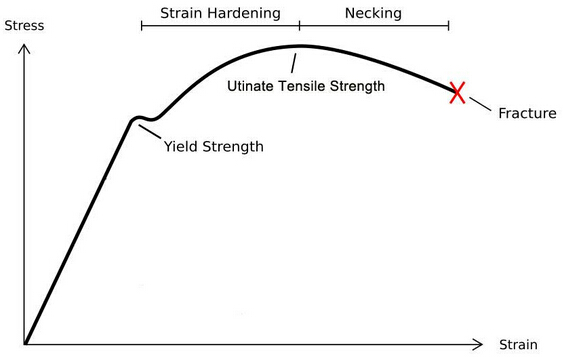

- Yield Strength

A yield strength or yield point is the material property defined as the stress at which a material begins to deform plastically. Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed. Yield strength of Q345B is 345 Mega Pascals. Like most steels of its grade, it suffers elongation before it pulls apart, typically at 20-21 percent of its initial length.

- Tensile strength

The tensile strength of a material is the maximum amount of tensile stress that it can take before failure, for example breaking. Steel tensile strength is expressed in units of force divided by cross sectional area; in the Metric system, this unit is known as the Pascal. One Pascal is a Newton per square meter. The tensile strength of Q345 steel is rated at 470 to 660 Mega Pascals.

- Hardness

Brinell scale hardness characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.

| Name | Grade | Chemical Composion% | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C≤ | Mn | Si≤ | P≤ | S≤ | V | Nb≤ | Ti | Al≤ | ||

| Q345 | A | 0.20 | 1.00-1.60 | 0.55 | 0.045 | 0.045 | 0.02-0.15 | 0.015-0.060 | 0.2 | |

| B | 0.20 | 1.00-1.60 | 0.55 | 0.040 | 0.040 | 0.02-0.15 | 0.015-0.060 | 0.2 | ||

| C | 0.20 | 1.00-1.60 | 0.55 | 0.035 | 0.035 | 0.02-0.15 | 0.015-0.060 | 0.2 | 0.015 | |

| D | 0.18 | 1.00-1.60 | 0.55 | 0.030 | 0.030 | 0.02-0.15 | 0.015-0.060 | 0.2 | 0.015 | |

| E | 0.18 | 1.00-1.60 | 0.55 | 0.025 | 0.025 | 0.02-0.15 | 0.015-0.060 | 0.2 | 0.015 | |

| Name | Grade | Tension Test |

180℃ bending test d=Diameter of bending center a=Thickness of sample (Diameter) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yield point, Mpa | Tensile Strength Mpa | Elongation % | Impact Power, AkV, J | ||||||||||

| Thickness (Diameter Side Length) mm | |||||||||||||

| ≤16 | >16-35 | >35-50 | >50-100 | +20℃ | 0℃ | -20℃ | -40℃ | ||||||

| ≥ | Thickness of steel (Diameter) mm | ||||||||||||

| ≤16 | >60-100 | ||||||||||||

| Q345 | A | 345 | 325 | 295 | 275 | 470-630 | 21 | ||||||

| B | 345 | 325 | 295 | 275 | 470-630 | 21 | 34 | ||||||

| C | 345 | 325 | 295 | 275 | 470-630 | 22 | 34 | ||||||

| D | 345 | 325 | 295 | 275 | 470-630 | 22 | 34 | ||||||

| E | 345 | 325 | 295 | 275 | 470-630 | 22 | 27 | ||||||

- NM400 steel plate

- low alloy steel plate

- Cor-Ten steel plate

- stainless steel plate

- pipeline steel plate

- pressure vessel steel plate

- abrasion resistant steel plate

- shipbuilding steel plate

- steel coil

- carbon steel plate

- Cold rolled steel coil

- testing

- quality policy Steel Grades

- EN 10130 cold rolled steel coil specification

- GB/T5213 - 2008 cold rolled coil

- JIS G3141 steel coil specification

- NM500 wear resistant steel

- NM450 wear resistant steel