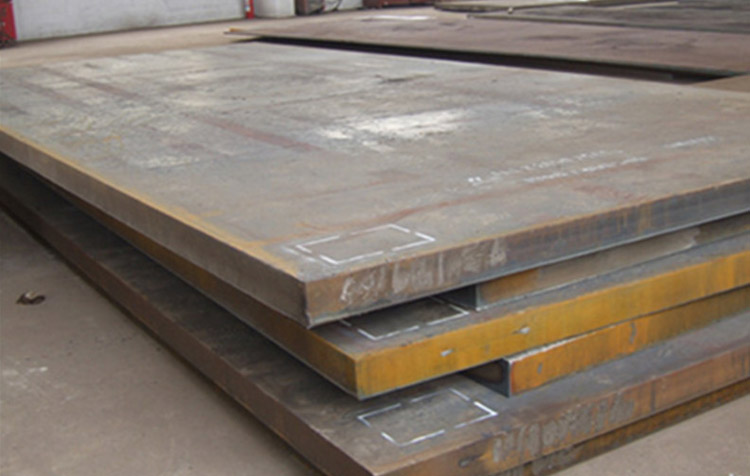

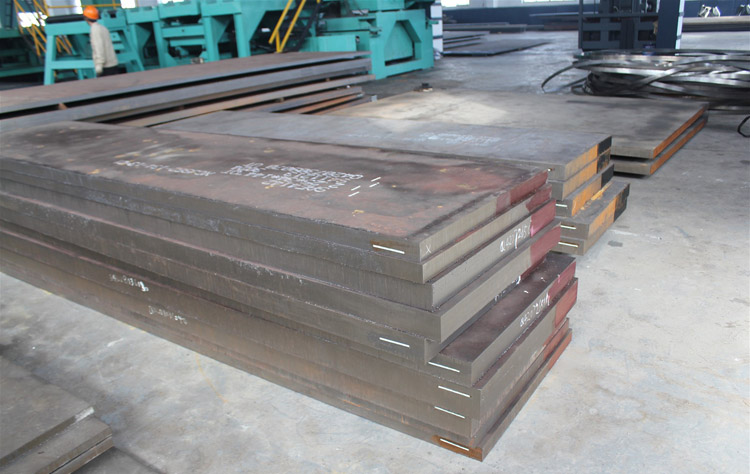

Abrasion resistant steel plate AR450 for sale

AR450 plate, also known as wear resistant plate, are abrasion resistant (AR) quenched and tempered alloy steels. This grade of alloy steel exhibits high abrasion resistance and hardness. The addition of carbon and manganese coupled with quenching and tempering increase the hardness of the steel and create a durable, impact-resistant surface. However, as hardness increases, formability and the ability to easily machine and weld the alloy decrease. Special machining processes are needed to prevent work hardening and chipping during manufacturing.

Abrasion resistant steels are not intended for structural applications. These steels should not be used for structural or main load-bearing members because of the possibility that brittle fracture may occur in these high hardness steels at the high stress levels encountered in such applications.

Thanks to High hardness and tensile strength give a steel high resistance to abrasion, AR400, AR450 and AR500 plate are used in applications where abrasive materials such as grains, coal, ore, cement, gravel, light aggregate, and earth are being handled. It is a common material for conveyors, chutes, linings, hoppers and handling equipment in the materials handling and mining industries, for example, ladles and lip plates of earth-moving machines, wearing parts of mining machines, concrete mixing plants and wood processing machines, platform structures, feeders and funnels.

- Chemical Composition Content %, Maximum

| Thickness mm/Cut lengths | Heavy Plates | C | Si | Mn | P | S | Al | Cr | Ni | Mo | B |

| 3 – 12 | 5–30 | 0.20 | 0.70 | 1.70 | 0.030 | 0.015 | 0.060 | 1.50 | 0.40 | 0.50 | 0.004 |

| -------- | (30)– 60 | 0.24 | 0.70 | 1.70 | 0.030 | 0.015 | 0.060 | 1.00 | 0.70 | 0.50 | 0.004 |

- Mechanical Properties of AR450 Plate

| Thickness mm Cut lengths | Heavy plates |

Yield strength Rp0,2 N/mm² |

Tensile strength Rm N/mm² |

ElongationA5 % | HardnessrangeHBW | Impactstrengtht°C KV J |

| 3 – 12 | 5 – 15 | 1000 | 1250 | 10 | 360 – 420 | -40 40 |

| -------- | (15) – 30 | 1000 | 1250 | 10 | 380 – 450 | -40 20 |

| -------- | (30) – 60 | 1100 | 1400 | 8 | 380 – 480 | -40 20 |

Welding

All the normal welding procedures can be used, provided that a professional welder pays special attention to the following factors:

- Use of correct working temperature.

- Correct choice of welding consumables.

- Suitable arc energy.

A reserved attitude to post-weld heat treatments should be taken because they have a tendency to weaken the most important property of these steels i.e. wear resistance.

Working Temperature

Increasing the working temperature slows the cooling of welded joints, which decreases the generation of a microstructure that is too hard and brittle and vulnerable to cracking in the heat affected zone. It is advisable to increase the working temperature of AR 450 steels when the combined plate thickness exceeds about 40mm. Generally a good working temperature of 100°C is enough to ensure a good result. However, when heavy and complicated structures are welded and when welding takes place under difficult circumstances, a higher 150°C – 200°C, working temperature is recommended. A higher working temperature than this may weaken the mechanical properties.

Welding Consumables

Either conventional, so called non-alloyed filler materials or so called alloyed materials that produce higher strength weld metals can be used as filler material. Generally non-alloyed filler materials are silicon and manganese alloyed and the strength of the weld metal they produce remains lower than the strength of the hardened base material.

An important advantage of non-alloyed filler material is that the softer weld metal they produce responds better to welding stresses. This is due to the better elongation and deformation ability of the soft weld metal in comparison with high strength weld metal. It is highly advisable to use low-hydrogen, basic filler materials so that the amount of hydrogen will remain safely low.

Heat-Treatment

The steels are not intended to be heat treated during or after fabrication. Tempering at moderate temperatures, 150°C - 200°C, is the only heat treatment which will without fail allow the steel to retain its original wearing properties.

Flame Cutting

A heat affected zone will build up on a thermally cut surface which is similar to the heat affected zone on a fusion welded steel surface. The surface hardens to a depth of 1mm-2mm during flame cutting and post heat results in a soft tempered layer below this. When flame cutting, the pre-heating and working temperature instructions concerning welding can be used as a guideline. In practice it is advisable to preheat when cutting plates, if the thickness is over 10mm.

The maximum allowable working temperature must be kept below 200°C in order that the wear resistance will meet requirements throughout the plate. The cooling of a cut surface must not be accelerated under any circumstances, on the contrary, the cooling of the plate surface can be slowed down if necessary. A plate brought in from cold outside storage must be allowed to warm up sufficiently before cutting.

- NM400 steel plate

- low alloy steel plate

- Cor-Ten steel plate

- stainless steel plate

- pipeline steel plate

- pressure vessel steel plate

- abrasion resistant steel plate

- shipbuilding steel plate

- steel coil

- carbon steel plate

- Cold rolled steel coil

- testing

- quality policy Steel Grades

- EN 10130 cold rolled steel coil specification

- GB/T5213 - 2008 cold rolled coil

- JIS G3141 steel coil specification

- NM500 wear resistant steel

- NM450 wear resistant steel