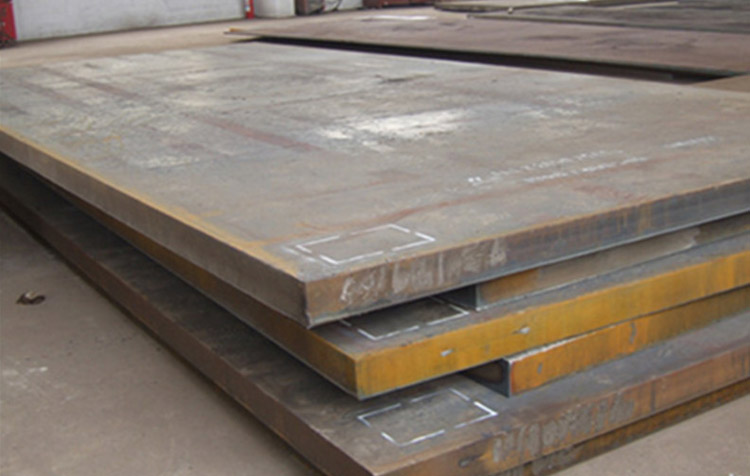

Cor-Ten A weathering steel plate

When COR-TEN is exposed to the atmosphere, it develops an initial layer of rust as ordinary steel does. But, as time goes by, this early product gradually converts to a fine-textured rust (protective rust) that tightly adheres to the base metal, providing a protective layer that both protects the base metal and suppresses further corrosion.

Since its development in the U.S. in 1933, COR-TEN has been used in every field where steel is applied, such as bridges, railway vehicle and buildings. Recently, unpainted applications of COR-TEN are attracting attention as being especially suited for resource savings and environmental concerns. Another growing application of unpainted COR-TEN is in conjunction with rust stabilization treatments on bridges, building exteriors and other structures. In this way, COR-TEN helps to reduce life-cycle costs and environmental burdens in a wide range of applications.

Corten A is a weather resistant steel created by alloying copper, chromium and nickel. Corten A has added phosphorous which makes the material best suited for gas flue applications and for aesthetic facias. The material is not recommended in heavy load bearing applications – in this case Corten B or S355J2W should be considered.

- Thickness: 6mm to 300mm,

- Width: 1500mm to 4050mm,

- Length: 3000mm to 15000mm

| C max | Si | Mn. | P | S max | Cr | Ni | Cu | Nb+V+Ti |

| 0.12 | 0.25-0.75 | 0.20-0.50 | 0.07- 0.15 | 0.030 | 0.50-1.25 | 0.65 | 0.25-0.55 | - |

| Grade | Permissible yield point ratio | Yield Strength MPa(min) | Tensile Strength MPa | Elongation % (min) | Bend |

| Corten A | - | 355 | 470-630 |

20 |

1t |

| Europe | UNI | Germany | France | UK | Sweden | India | Japan |

| S355J0WP |

Fe510 C1K1 |

- |

E 36WA3 |

WR50A |

- |

- |

- |

- NM400 steel plate

- low alloy steel plate

- Cor-Ten steel plate

- stainless steel plate

- pipeline steel plate

- pressure vessel steel plate

- abrasion resistant steel plate

- shipbuilding steel plate

- steel coil

- carbon steel plate

- Cold rolled steel coil

- testing

- quality policy Steel Grades

- EN 10130 cold rolled steel coil specification

- GB/T5213 - 2008 cold rolled coil

- JIS G3141 steel coil specification

- NM500 wear resistant steel

- NM450 wear resistant steel